Summary

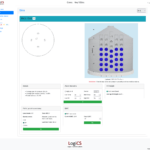

Ceres is a grain bin monitoring and fan automation system that supports both flat and hopper-bottom bins. Each bin can have one to several sensor cables installed. Each cable has temperature and humidity sensors positioned at intervals along its length. The positions of the sensors and their readings determine both the average EMC (equilibrium moisture content) of the grain as well as the fill height of the bin. The sensor readings are captured each minute along with weather station data (outdoor temperature, humidity, and rain detection). The data is run through an algorithm that determines how to control the fans. Fans are controlled with the goal of maintaining a target EMC for the grain.

Fans can be controlled manually on site with a physical switch, manually via the app, or automatically using the algorithm.

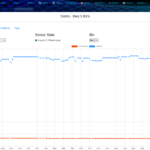

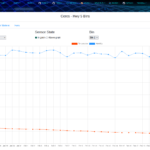

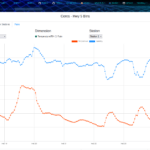

Up to three years of trend data is maintained for average bin conditions, weather stations, and fan runtimes. These trends can be viewed in line graphs and table views of various intervals (i.e. Last 24 hours, Last 7 days, Last 30 days, etc.).

System Hardware

A setup can handle one or several (20+) flat and hopper-bottom bins. Each bin can have one or many (10+) sensor cables, often with one or more going down the middle of the grain and the others around the outside (about 9 feet in from the outer wall). The bin’s cables are all wired in to the same bus (weatherproof enclosure with a terminal block at the top of the bin). Two wires are routed from the top enclosure to another temperature controlled enclosure at the bottom of the bin which houses an Arduino Pro Mini microcontroller. The Arduino captures the cable sensor readings via 1-Wire protocol and stores them in memory

where they await retrieval from a PLC (Programmable Logic Controller) via Modbus RTU. In a wireless setup, the Arduino’s enclosure will also house a slave PLC to c

apture the readings from the Arduino so they can be read by the master PLC over Modbus TCP using wireless radios. With a non-wireless setup, there is only the master PLC hardwired to each bin’s Arduino (two wires per) to facilitate Modbus RTU communication. The master PLC resides in the main panel (also temperature controlled) along with a Fitlet single-boa

rd computer and a UPS (uninterrupted power supply). The Fitlet interfaces with the master PLC via Modbus TCP and serves a database-driven web application on the home network. Long-range wireless radios can connect the home network up to five miles (depending on conditions) if needed. Remote connectivity is achieved outside of the home network via a VPN connection to a reverse proxy server in the cloud.

System Software

The system is managed with the web application served by the Fitlet device inside the main panel. It can be accessed using any web browser from a public URL, which will be provided. It is fully mobile-responsive to work great on computers and smartphones. The application features real-time monitoring of grain moisture content, trend data, and fan control. There are also alarm notifications that can be sent via SMS and/or email.

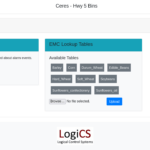

In auto mode, outdoor and grain conditions for each bin are checked and analyzed every minute to determine fan state. You can set a target EMC per bin and the system will control the fans accordingly. If EMC is below target and outdoor humidity is higher than average grain humidity, fans will come on to raise grain moisture content. Various other factors are also checked against, such as rain conditions to not run fans in the rain, dew point to avoid sweating the bin, empty bin, etc. EMC is determined by sensor humidity and grain type using lookup tables. There are currently nine default lookup tables for common grain types. You can also upload a custom lookup table if a default isn’t provided for your grain.

The system can also estimate fill height and bushels for each bin. It does this by checking incoming sensor readings for more than a three-degree swing in temperature in the last 24 hours on each sensor. If it swings more than three degrees, then the sensor is determined to be above the level of the grain (uncovered). The bushel estimate is calculated from the bin radius and grain height.

Trend data can be viewed as a table with an accompanying line graph.

Current trends include:

- each bin’s average covered sensor temperature and humidity

- each bin’s average uncovered sensor temperature and humidity,

- weather station temperature and humidity

- weather station rain states (10 minute intervals, no graph)

- fan runtimes

Trend periods are applied to each trend. Currently we have:

- Last 24 hours

- Last 7 days

- Last 30 days

- Last 6 months

- Last 12 months

- All time (3 year limit)

In the future we plan to trend each individual sensor to provide finer-grained (pun not intended) analysis.

Why you need it:

- Save time and money by remotely monitoring and controlling your grain bins.

- Gain deeper insight into the current state of your grain.

- Receive alarms which indicate hot and cold spots or fire.

- Maintain optimal EMC throughout the year by letting our AI take the wheel.

- Use trend data to plan for next harvest.